Products

We are full-service provider for customized industrial refrigeration, storage and ripening systems, from design to assembly, project implementation and management.

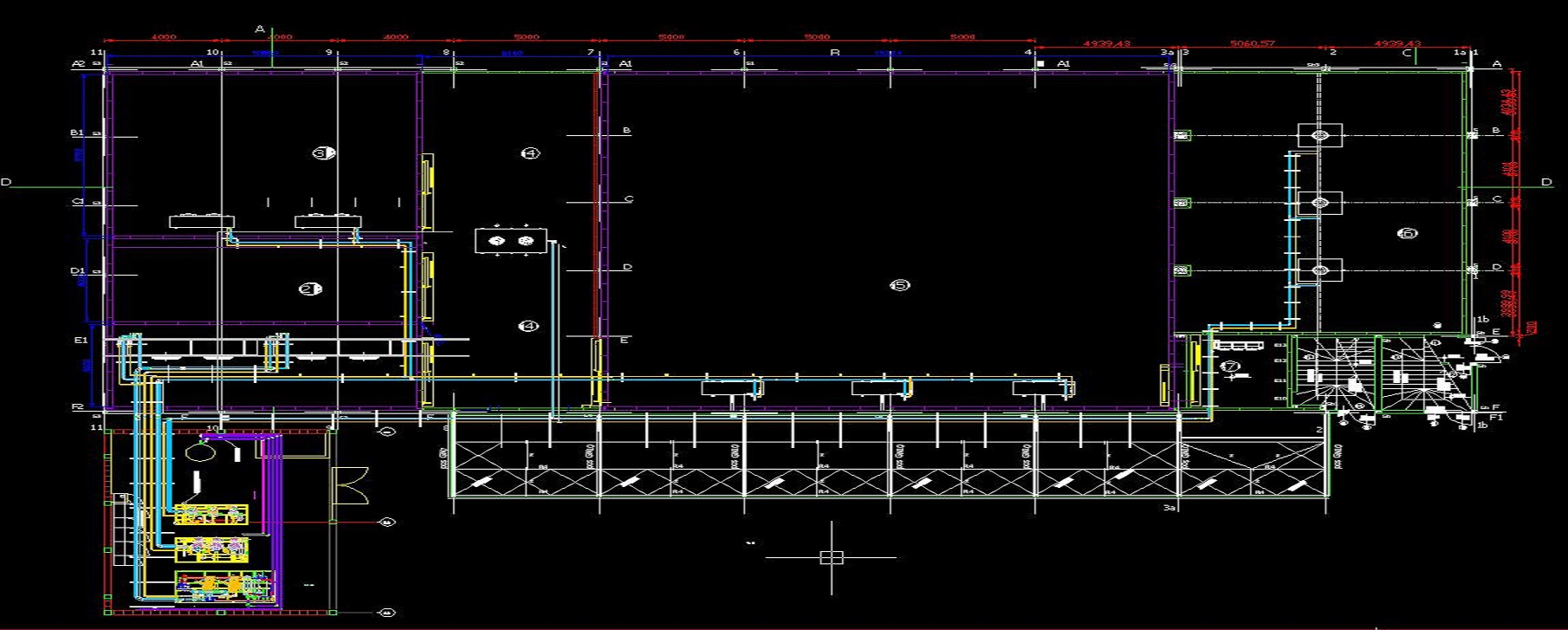

Cold storage plants for fruit

and vegetables

Cold storage plants are buildings with special purpose. They are used for storage of fruit and vegetables for a long period of time, while the quality of the stored goods remains unchanged.

Storage period and regimes primarily depend on the type and variety of the product being stored. The best way to preserve the freshness of the product as well as to prevent the growth of microorganisms is cooling and freezing.

Depending on the applied cooling technology, we can offer you two types of cold storage plants:

- Standard cold storage,

- ULO cold storage with controlled atmosphere

Without a cold storage, most vegetables could not stay fresh for more than a few days. As soon as a fresh product gets picked, it starts to go bad and harmful bacteria develop on it.

For this purpose, we install warehouses for various types of vegetables, such as potatoes, beet, onions, carrots, cabbage, etc. in order to optimize the use of space and transparency, as well as functional manipulation of fruits. Vegetable storage facilities allow storage in various positive temperature regimes and are equipped with additional technologies, such as ventilation with fresh air, air heating, humidification, additional internal air circulation through stored vegetables, all of which helps to extend the shelf life.

The warehouses can be of different capacities, from the smallest (1,000 tons) to the largest (100,000 tons and more).

Our cooling system allows:

- Reduced respiratory and degradation activity of the enzymes ·

- Reduced internal water loss and withering, with the help of high-quality cooling equipment and additional humidifying system as needed

- Slower or limited development of microorganisms responsible for rotting

- Reduced production and concentration of natural ripening agent, ethylene, through ventilation system by fresh air supply and precise temperature conditions in storage rooms

Our cooling system provides the highest possible quality of vegetables for the consumer.

Deep freezing tunnels

The modern way of processing fresh food products requires deep freezing. We make deep freezing tunnels as individual units or within the entire cold storage plant. Tunnel production is specific in relation to the type of food that is freezing. Tunnels are of different capacities and dimensions, and depending on your needs, they are adapted to the type, quantity and time of freezing.

Refrigerant means and goods may be in contact and on the basis of this there is:

- Direct freezing – directly in contact with the food that is freezing, and should not react with food ingredients or be poisonous to humans,

- Indirect freezing – using fluids, we first cool down the refrigerant body that is the intermediary, and with it we subtract the heat of the foodstuffs that are freezing.

In addition to the refrigerant bodies, ventilation devices for forced circulation of cold air are installed in these devices as well. Well known devices of this type include:

- A classic tunnel,

- Fluidized freezing devices.

A classic tunnel is suitable for freezing almost all types of products and therefore is called a universal tunnel. It is made as a heat-insulated chamber. The products are frozen in plastic crates which are in metal pallet boxes.

In such tunnels, evaporators can be placed vertically along the longitudinal wall or divided into two vertical sections between which the pallets are placed. Classic tunnels are irreplaceable when it comes to the freezing of goods packed in larger packaging units.

Fruits can be packaged before or after freezing (whole or sliced fruit). Raspberry is the most common fruit frozen into a Rolend and most often intended for export.

Fluidized freezing device – Fluidized freezers are the most modern cold-air freezers. The feature of this freezing mode is that the freezing time is short, less than 10 minutes. The airflow velocity is usually 6-7 m/s. The operating principle of these tunnels is based on the creation of a strong cold air current which, by moving upwards, lifts products that act as a “fluid” up from the belt conveyor.

Freezing tunnels in the fluidizing layer can be without the belt, with one or two belts. When it comes to a fluidizer with the belt, the belt speed can be adjusted and it depends on the type of product. On the first belt, the shape of the product is fixed by surface freezing and the air flow is more intense there than it is on the second belt. Products that are frozen uniformly are distributed along the entire length of the belt in a layer of thickness from 20 to 60 mm. The air temperature in the tunnel goes from -35 to -40 . The tunnel capacity is 2-10 t/h, and the freezing time is about 5 cm/h.

Electrical installations

Electric cabinets are used to power and control individual cooling devices. Based on our own projects in this field, we produce electric cabinets using distribution equipment, controllers and microprocessor-based control systems of world renowned manufacturers.

Manufactured electric cabinets have been tested and subjected to all mandatory tests in terms of safe and reliable use. A declaration of conformity is issued for each electric cabinet, in accordance with the Low Voltage Directive (LVD) 2006/95/EC and the Electromagnetic Compatibility Directive (EMC) 89/336/EEC. This confirms the quality and safety of products. Please contact us if you would like some more information, it will be our pleasure to find the best solution together with you.

Central supervisory system FrigoMontaza

For cooling, storage and ripening systems, we develop and install appropriate application control software – Frigo Montaža central supervisory system – to control all operating and protection parameters and manage them.

The Supervisory Control And Data Acquisition, SCADA, is installed on a single PC, with custom software that provides a complete overview of the operation of the cooling system in the facility, including the setting and control of important technological parameters:

- Regulation of the cooling system and technological operating parameters

- Record data on temperatures, pressures and possible problems

- Visualization of actual values of important operating and control parameters

- Printing of information from a data warehouse in the form of a table or diagram

- Visualization and signaling for possible problems in the operation of the cooling system, whereby the responsible person is sent an SMS message on the problem

- Internet connection of the Frigo Montaža central supervisory system, from a computer at a remote location to the facility

- Please contact us if you would like some more information, it will be our pleasure to find the best solution together with you.

Mechanical installations

Cooling unit – The basic component of the cooling system is a cooling unit, which can consist of one or more compressors. By using compressors of renowned European manufacturers, internally dimensioned constructions and a special selection of components, we produce cooling units to ensure reliable and efficient operation.

Our cooling units are also used in industrial and commercial cooling systems and meet all the requirements of the Pressure Equipment Directive (PED), which is confirmed by the obtained certificate.

Please contact us if you would like some more information, it will be our pleasure to find the best solution together with you.

Pump stations – Pumping stations are devices for delivering cold water or mixtures of glycol through pumps to coolers in warehouses, banana ripening chambers or other consumers. The pump station is mounted on a metal frame, on which the pump, a three-way valve and a container with a heater are interconnected.

We make pump stations using components of renowned manufacturers and our own components. Pipelines are made of carbon or stainless steel.

Please contact us if you would like some more information, it will be our pleasure to find the best solution together with you.

FRIGO MONTAZA

Frigo Montaza is trusted and reliable provider using high-end and advanced technologies for refrigeration, storage and ripening systems to the highest international standards.

FRIGO MONTAZA TECHNOLOGIES